Digital Manufacturing Class – Ecolops Tile

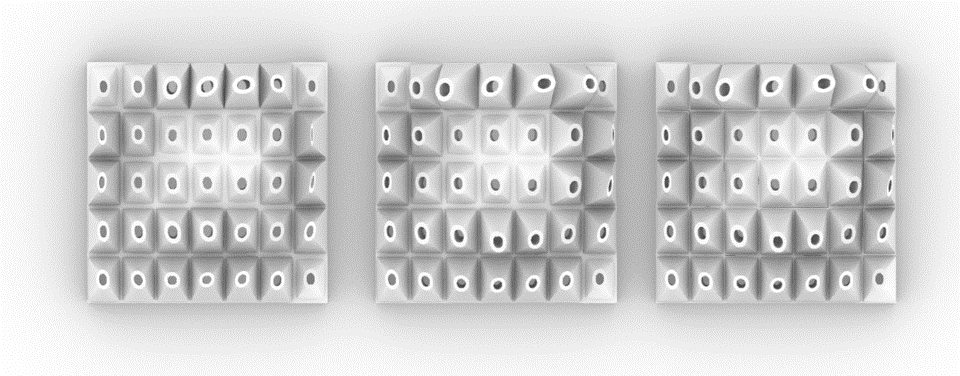

Seed planter tile concept

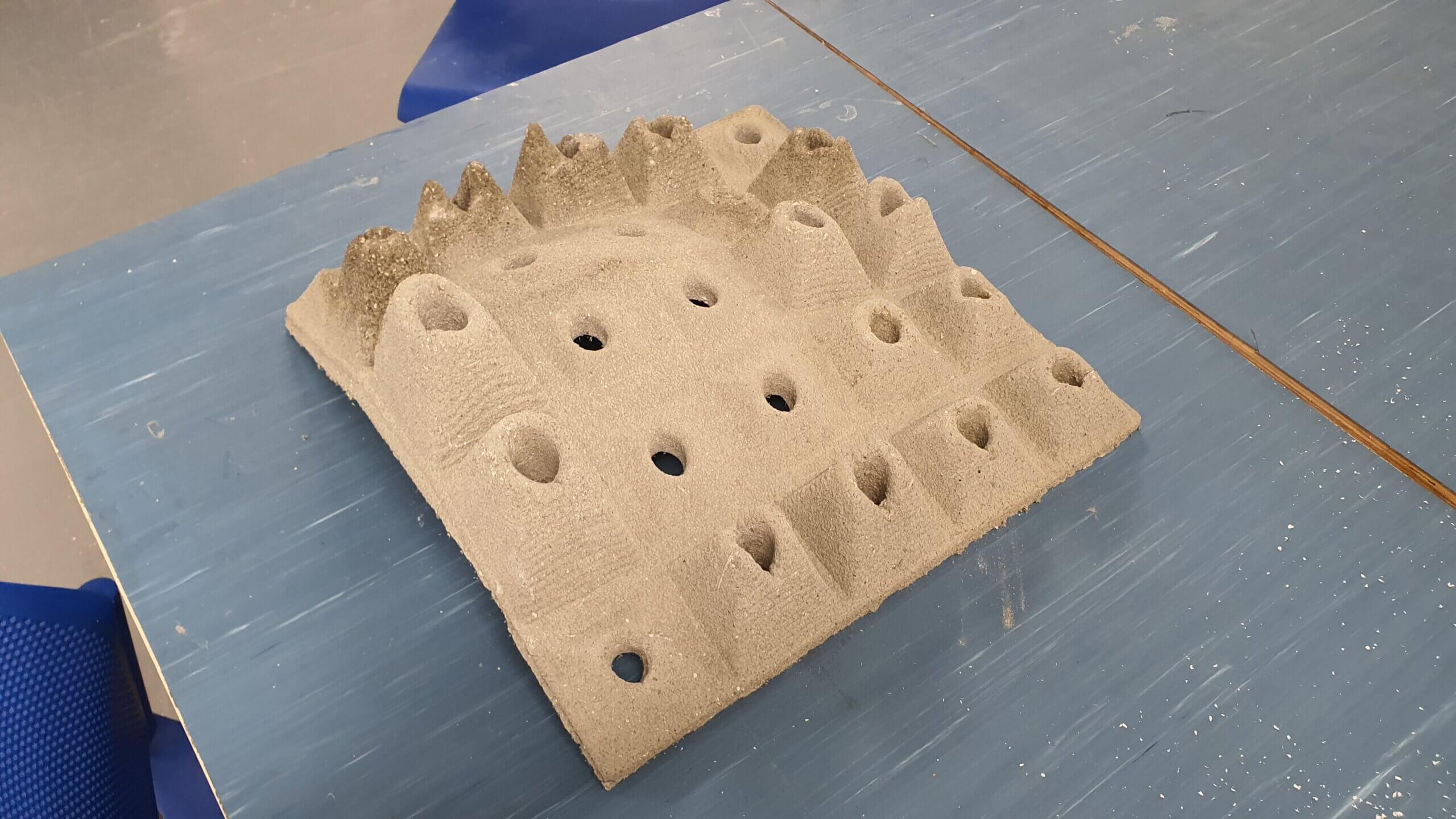

This planter concept for chia seeds was designed as an example for students from the Digital Manufacturing Class in order to show the maximum capacities of the 3-axis CNC milling machine that the Technion operates.

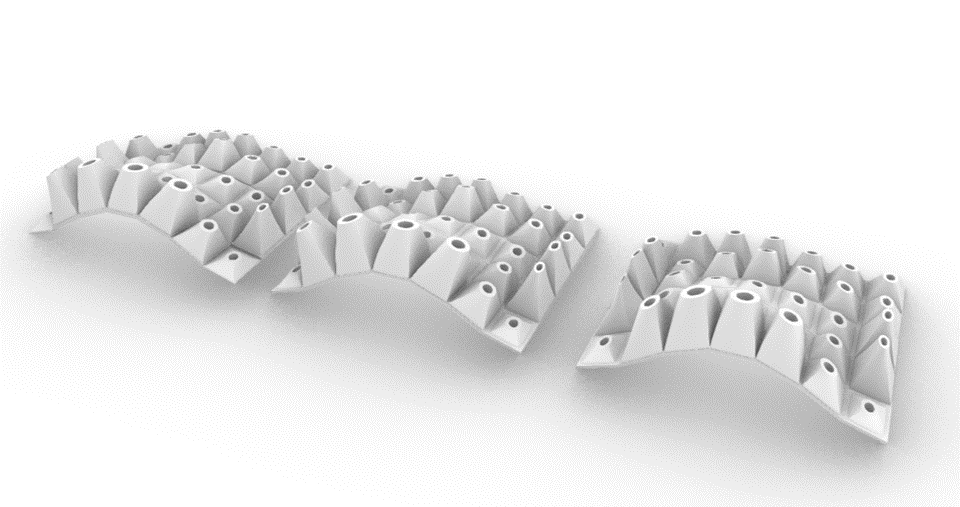

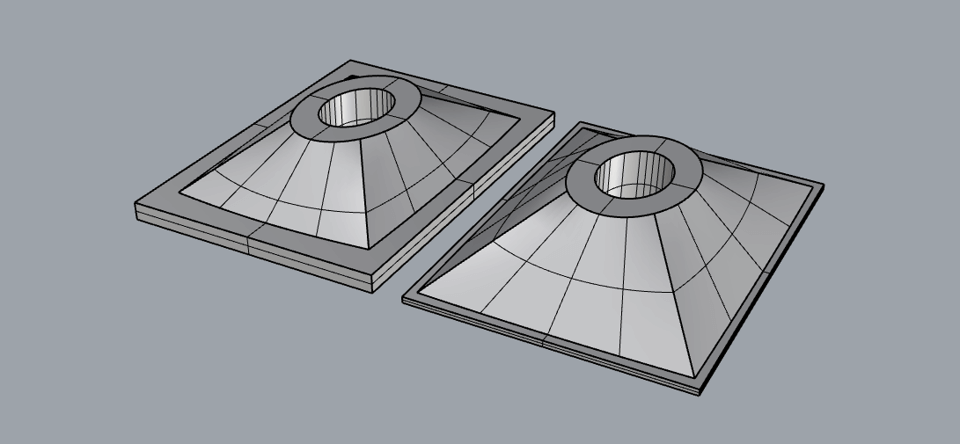

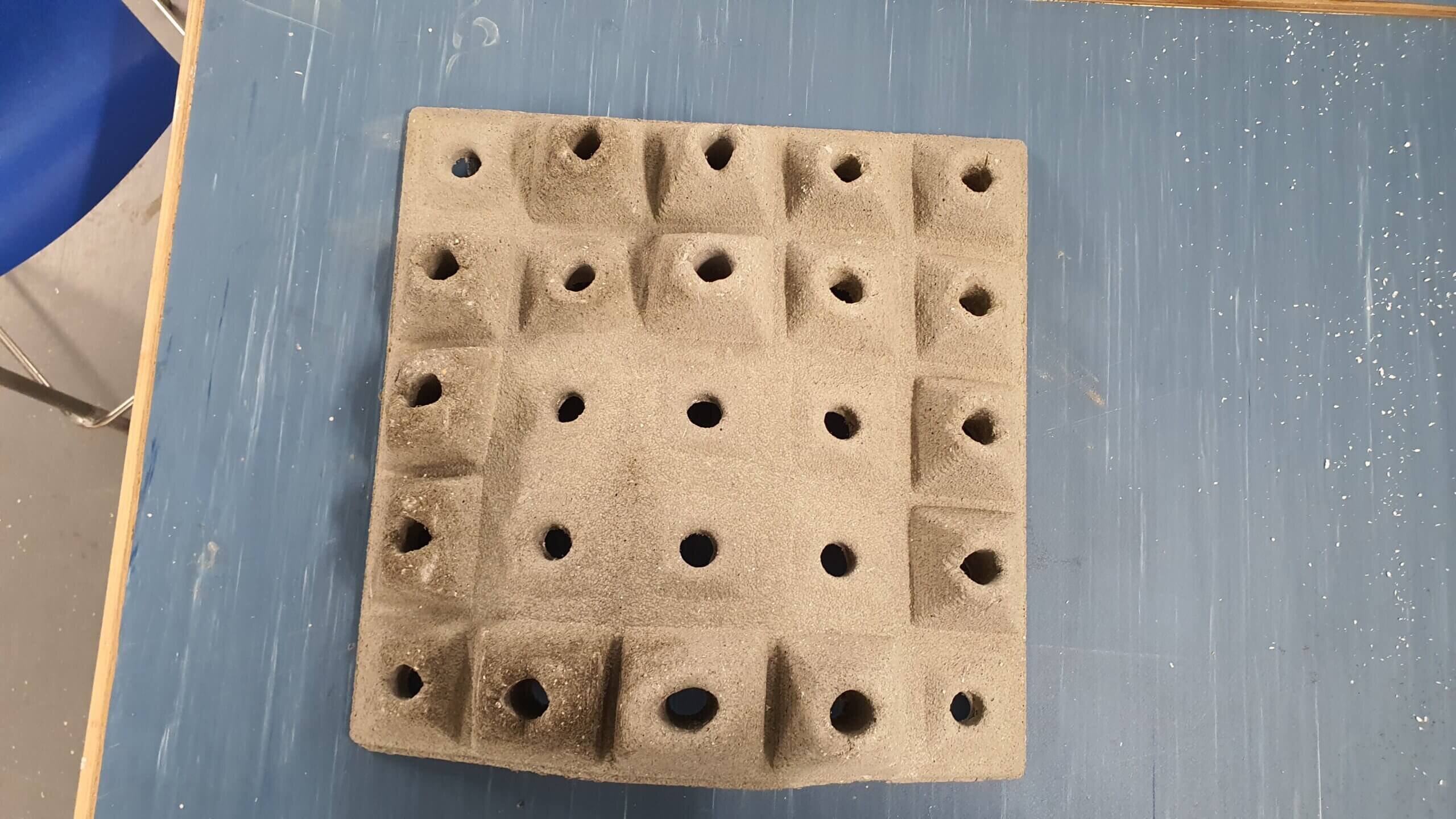

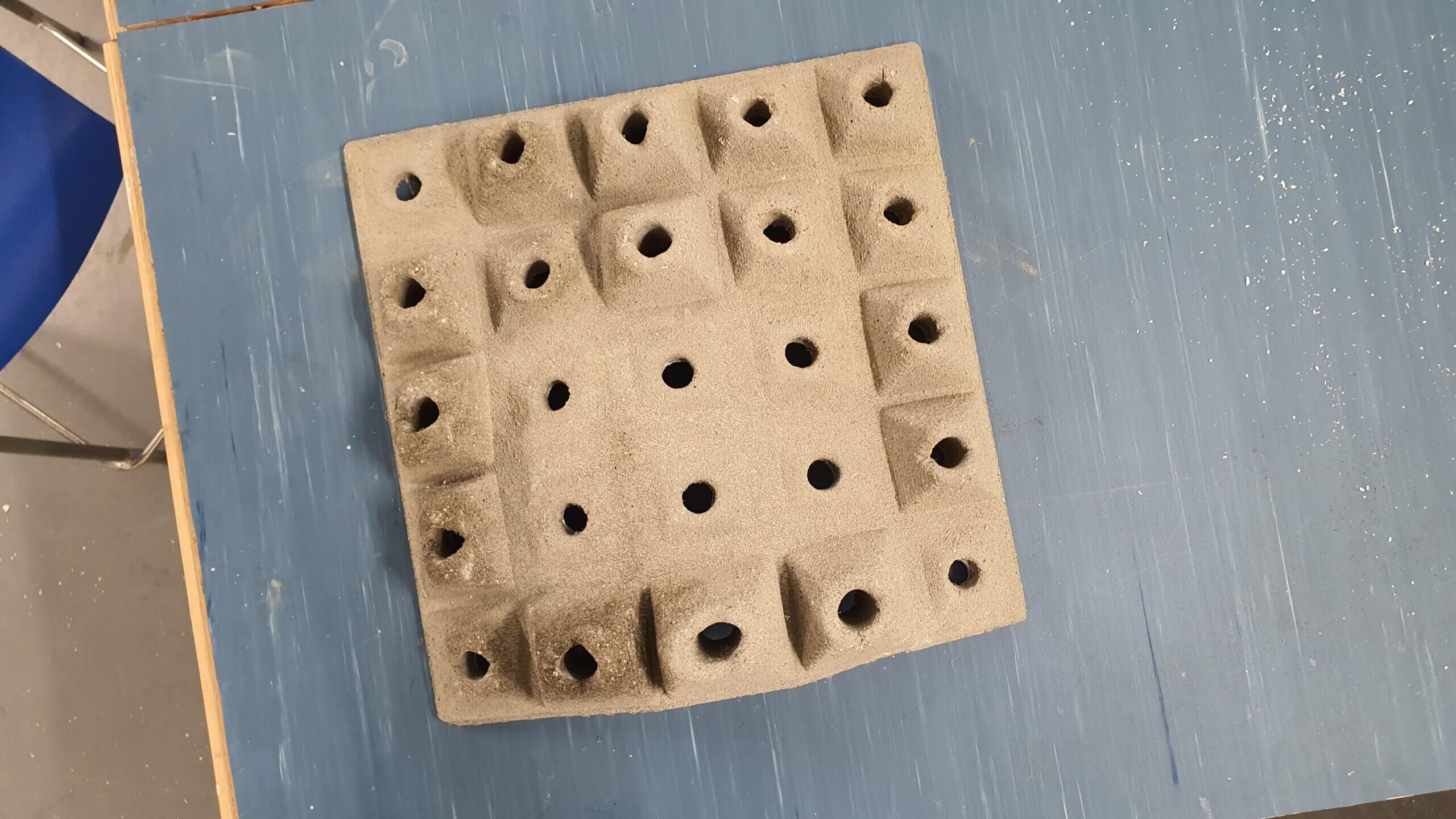

Each cell from the tile was first designed as a 3d geometry in Rhino 3D and then through grasshopper was populated onto a double curved geometry surface to create a complex 3D tile.

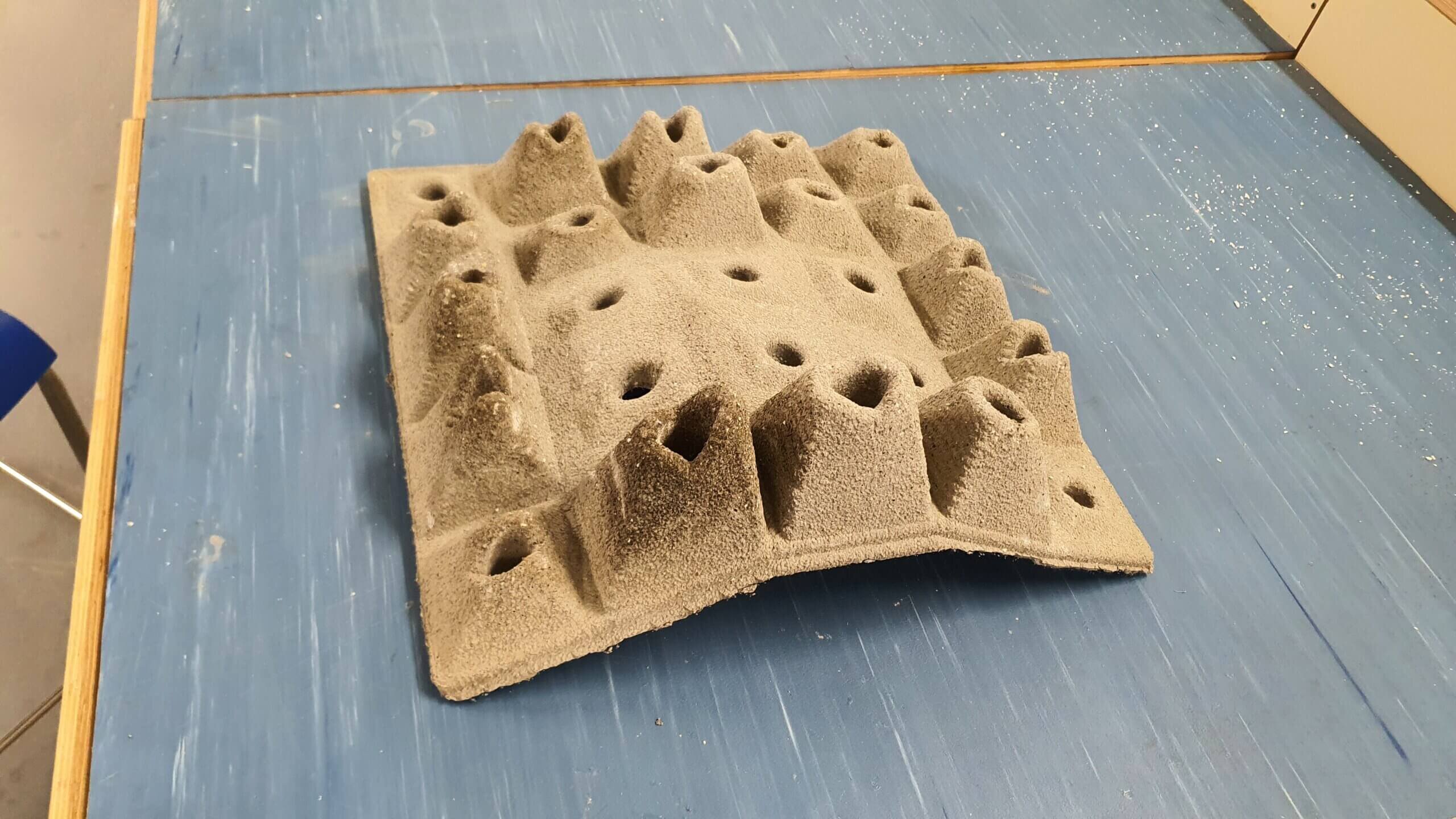

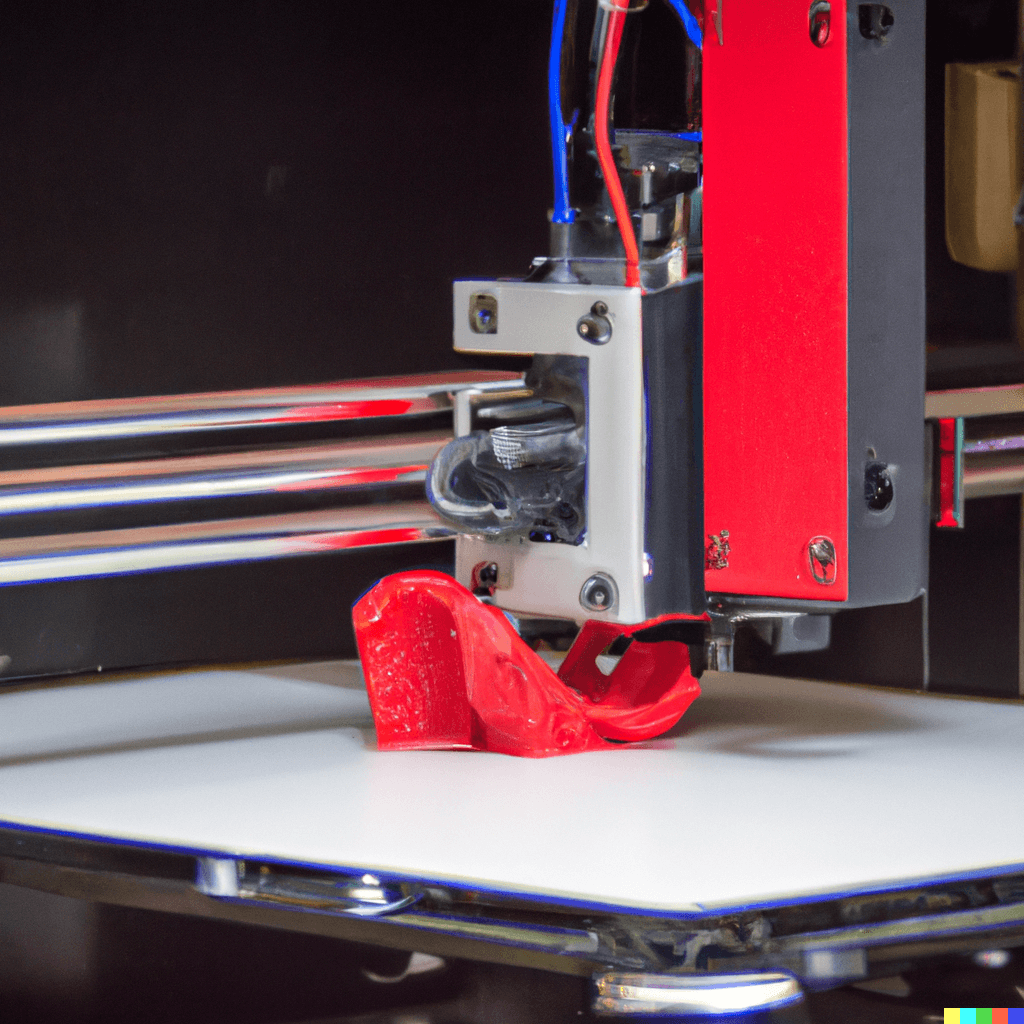

the tile was first 3D printed to get an idea about the proportions and physical geometry of the tile.

The process of creating this tile included 3 main steps: Rationalization, Optimization, and Manufacturing.

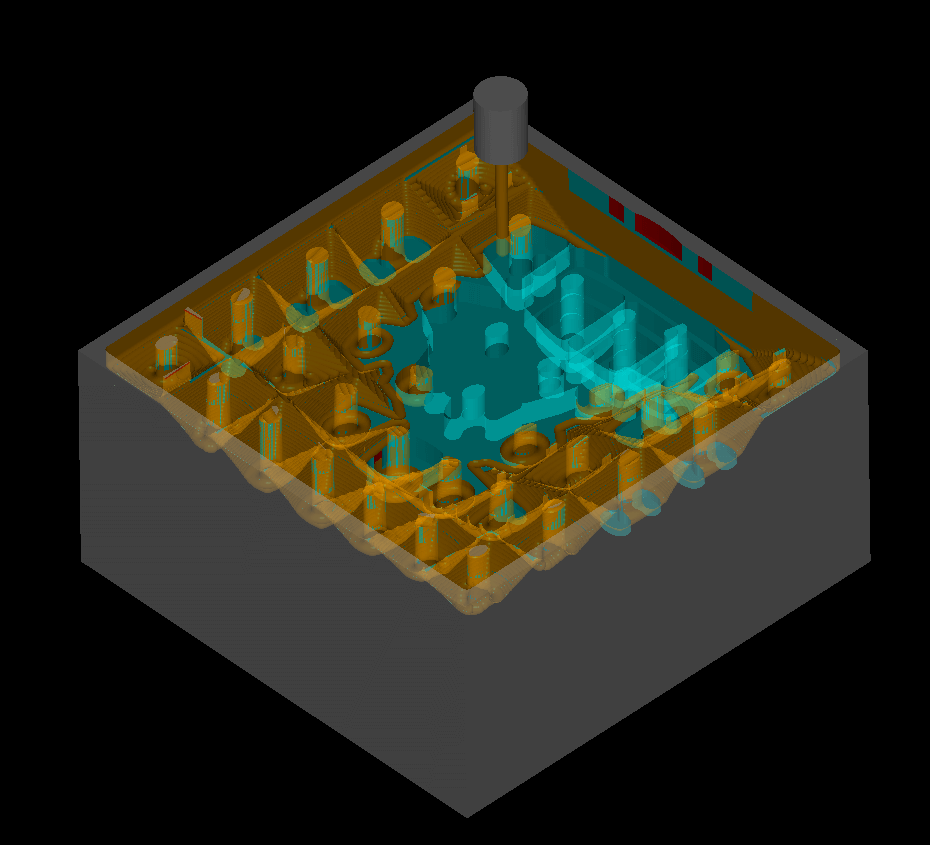

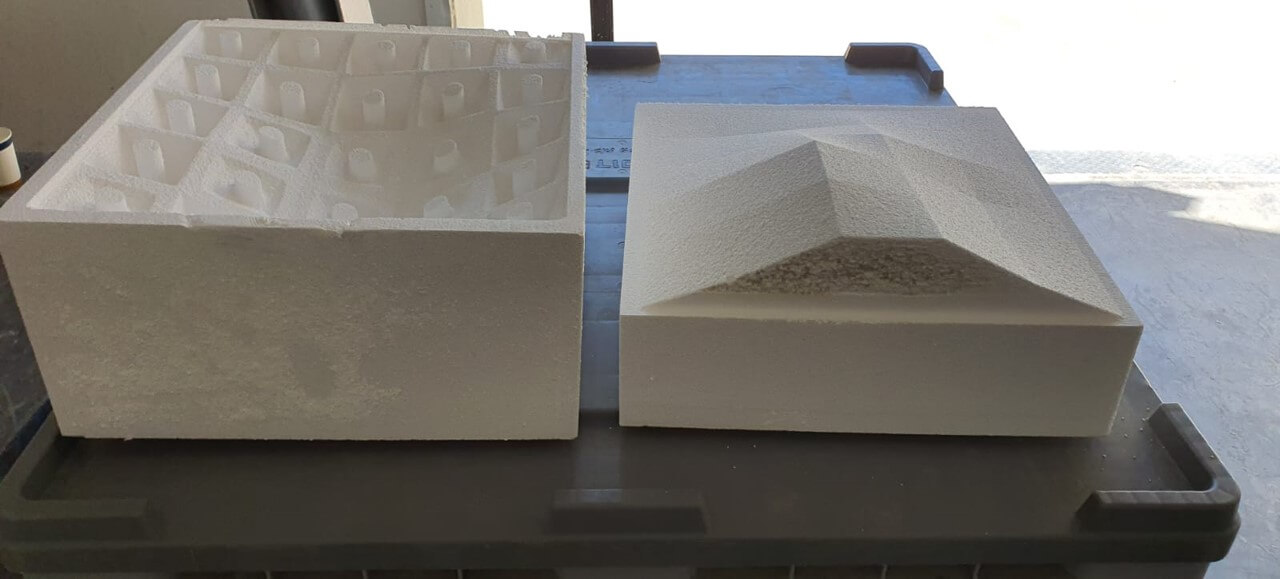

the tile was first 3D rationalized to make it fit for CNC milling, the process included: reversing the “positive” geometry to “negative” geometry as a mold, fixing extraction angles, geometry adjustments, max height adjustment to fit the CNC capabilities, Etc.

Secondly, the tile was optimized for CNC milling, the process included CAD and CAM adjustments to ensure the success of the milling process, we had a few failures that were fixed by thicking the walls and points of the geometry.

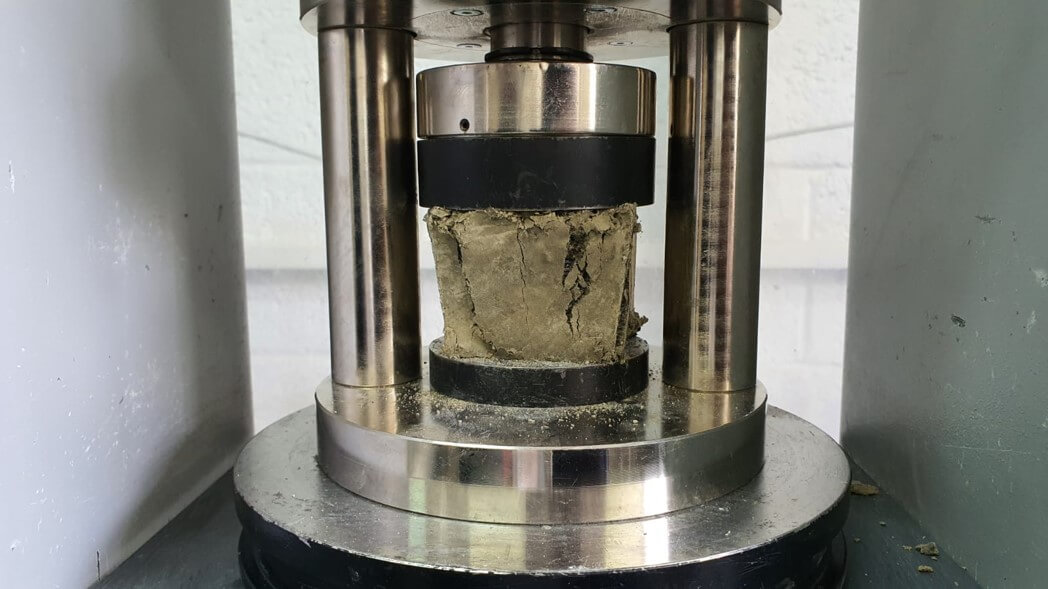

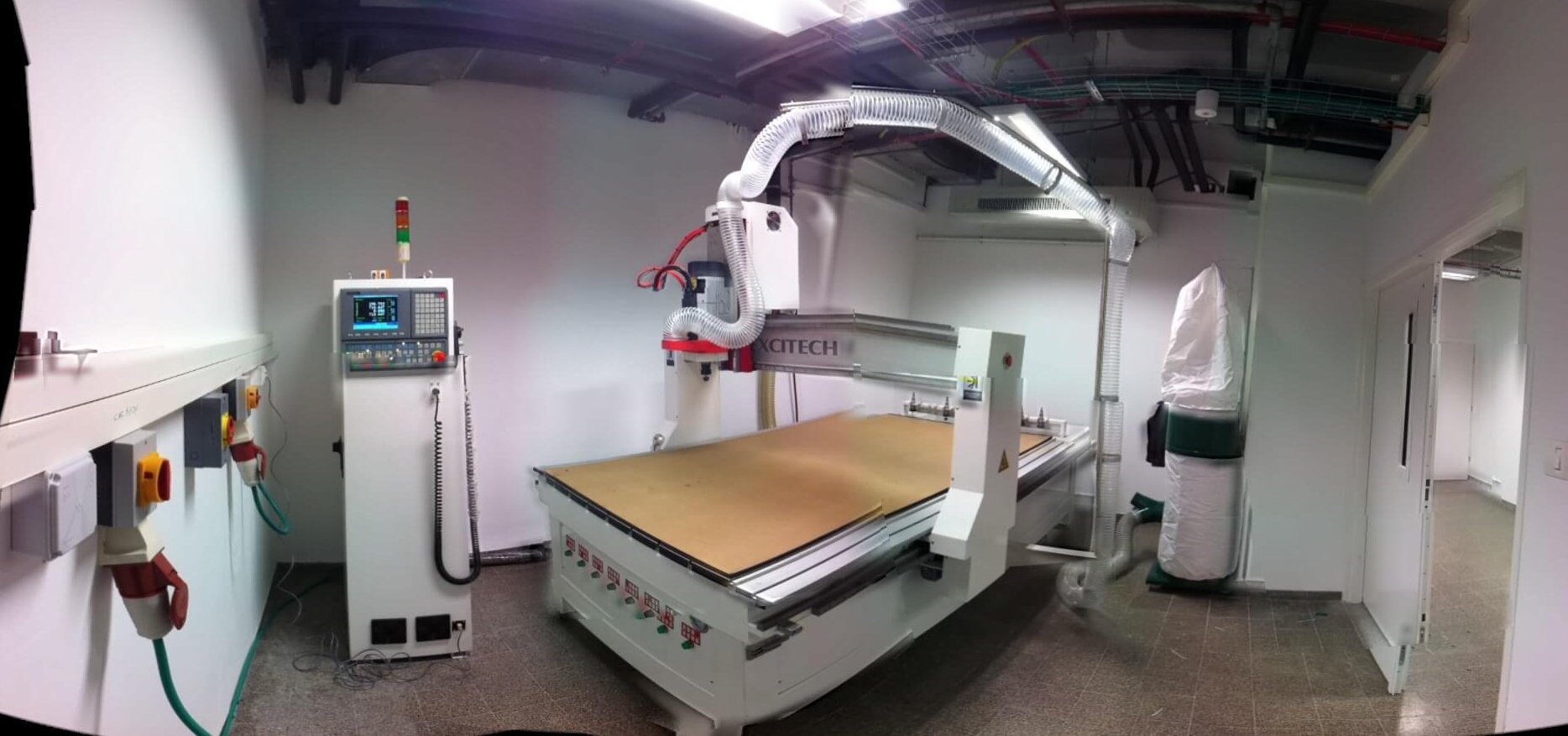

Thirdly, Manufacturing was composed of 3 main steps, (1) Manufacturing of the mold from styrofoam by CNC milling, (2) Casting the concrete in the mold and drying over 1 week, (3) Extracting the concrete tile from the mold, *the mold did not survive the process and was destroyed upon extraction.

overall the project was a success and was the basis for 18 student projects.

Design computation

Performance-oriented architectural design

Sustainable architectural design

Human spatial perception/emotions

Computer-aided manufacturing

Mycelium in architectural and industrial design

Ezra's academic pursuits are in the fields of Virtual Architecture and the Metaverse:

Ezra's master's thesis is on the subject of “Gamification of the rehabilitation process through Virtual Reality” and offers a unique hybrid aptitude in VR gaming and complex generative 3D design and manufacturing.

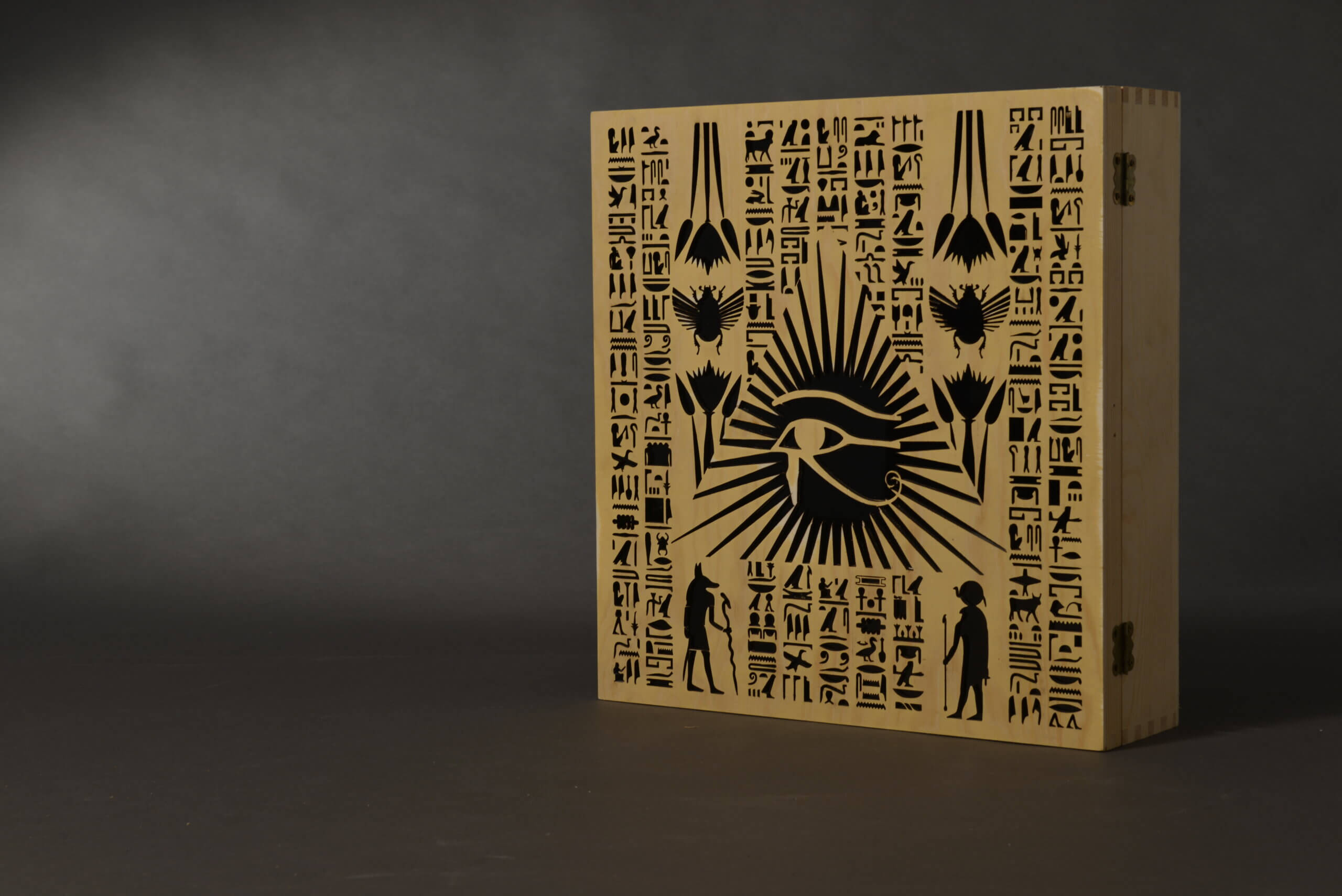

The process of designing and manufacturing the mold and the final concrete product. Photos by Ezra Ozery

Technical Info:

3 axis CNC

3D printing

Materials in use:

Cement

Styrofoam

Cost and time:

CNC work time – 2.5 Hour cutting

CNC file preparation – 1 Hours

CNC cost – 298 ILS at student rate

Materials cost:

Styrofoam – 51cm*51.5cm*25.5cm, 2pcs. – 130 ILS

Total Project cost:

428 Nis

All Rights Reserved. 2025 © Faculty of Architecture and Town Planning. The Technion, Haifa. Created by Catom web design.

Accessibility Statement || Privacy Policy