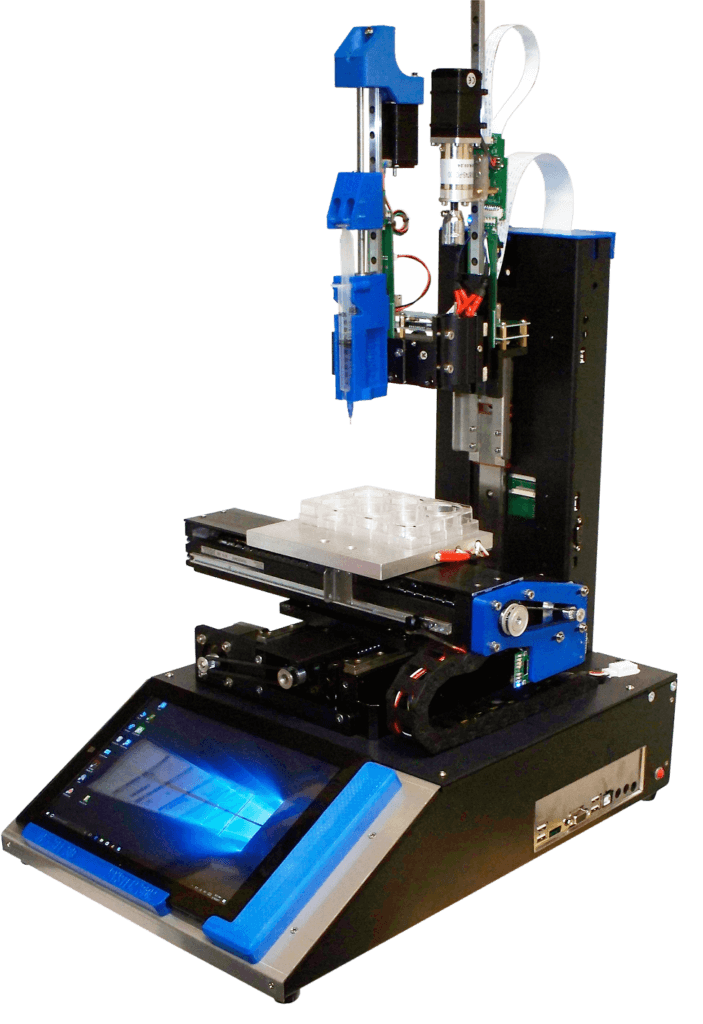

Hyrel 3D Engine HR

3D bioprinter

Designed specifically with the needs of the Bioplotting / Bioprinting community in mind!

All Rights Reserved. 2022 © Faculty of Architecture and Town Planning. The Technion, Haifa. Created by Catom web design.