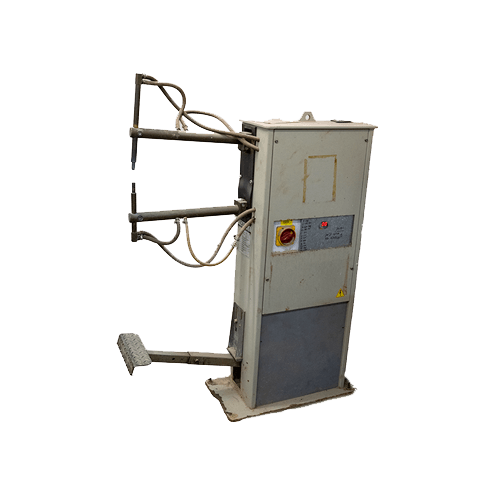

Resistance Welder – TECNA

TECNA 4602N Pneumatic Rocker Arm

rated capacity 16,0 kVA 50% ED

welding power 35,0 kVA max.

contact pressure capacity 240 daN

throat 280 mm

electrode stroke 15 – 85 mm

weight 116 kg

range L-W-H 1000 x 400 x 1100 mm

Furnishing:

– Spot welding machine from a training workshop

– Welding control TE 90 Mark II

– Cooling device / container

Welding control TE 90 is a microprocessor control for single-phase

resistance welding machines. The welding controller has the task of

To control machine elements, especially the SCR, which controls the adjustment

of the control the welding current. The duty cycle that the TE 90 performs is

described using the programming parameters.

– SCR synchronous control, welding time regulation by phase cut

– Simple programming via 4 keys

– Current rise and pulses

– Single point and automatic

– Secondary current compensation for welding

dirty metal sheets and wires

– Welding time lock optimizes current draw from the mains

– Solenoid valve 24 Vdc 7.2 W max. with output protected against short circuits

- Air-operated, lube-free cylinder eliminates oil mist in the shop environment.

- Electrode force is adjustable via integrated filter / regulator combination.

- Reduce shop noise with integrated speed control valves, shock absorber for end of cylinder stroke, and air exhaust mufflers.

- Two-stage electronic footswitch initiation (1st stage closes tips without welding, 2nd stage initiates weld schedule.)

- Pre-wired to accept a second footswitch (Option 72977).

- A second footswitch allows for immediate recall of a second weld time / current setting. This is helpful when different settings are required on the same workpiece.

- PINCH POINT SAFETY OPTION: WSI-supplied TECNA Rocker Arm Welders are available with UNITROL Soft Touch Safety for pinch point protection.

All Rights Reserved. 2025 © Faculty of Architecture and Town Planning. The Technion, Haifa. Created by Catom web design.

Accessibility Statement || Privacy Policy