Preparing your file for a 3-axis CNC Operation

3-Axis CNC

Important Information:

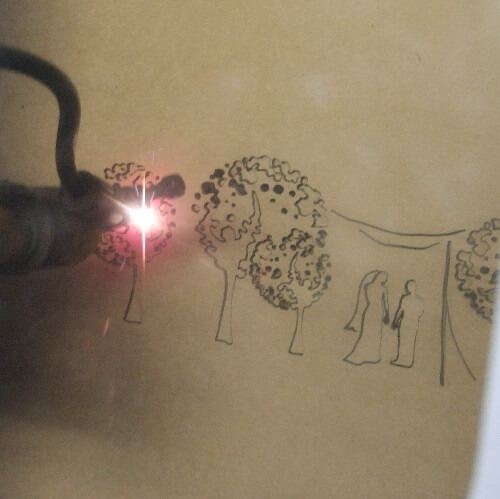

- There are 3 kinds of CNC operations:

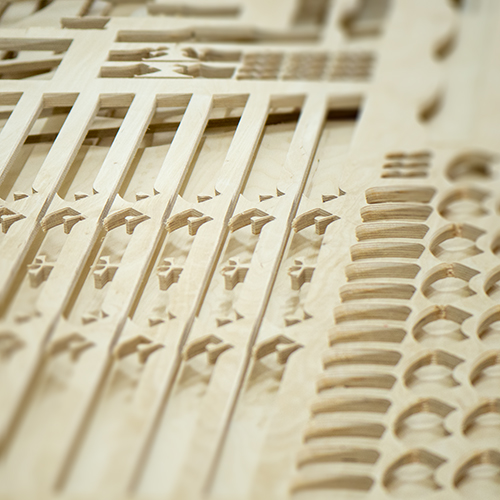

- 2D – milling flat shapes from a material.

- 2.5D- milling flat shapes from a material with different elevations\text.

- 3D – milling 3d surfaces from a material.

- Machine working area: 1220(w)x2440(l)x200(h)mm

- possible milling materials: hard wood, soft wood, MDF, Styrofoam.

- CNC machine work with the measurement unit (mm)

While preparing file for CNC Milling please pay attention for the following instructions:

(1) create a 1220x2440mm framework that starts from the 0.0.0 as so.

(2) Take 20mm offset from this frame to the inside. this is your the milling area.

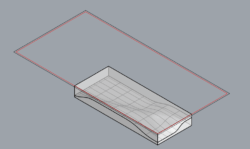

(3) create a solid in the shape of the material that you plan to use and place in inside the frame that the upper part of the shape is at 0 on the z-axe.

(4.1) 2D, 2.5D Operations:

-

- create a curves for the shape you want to get.

- place all curves on the z-axe at elevation 0.

- closed curve could act as a:

- cutout – milling moves on the exterior side of the contour.

- pocket – milling remove all the material from the inside of the contour.

(4.2) 3D Operation:

-

- create a 3D surface

- place it on the exact spot inside the material ( the machine will remove all the material above the surface).

After those steps please get in touch with the CNC team in the lab for inputs & thoughts and consultation.

When the file is ready and approved by the lab team we will set an appointment to start the process.

what we expect to get from you before the appointment:

- DXF file -Which includes all the curves sorted to different layers by operation.

- STL file – Which includes solid in the material shape.

- Rhino 5 file – Which includes the 3D surface.

- Rhino file – Which includes all the above together.

Before we start the milling operation you will see a simulation of the outcome to approved the process.

All Rights Reserved. 2022 © Faculty of Architecture and Town Planning. The Technion, Haifa. Created by Catom web design.